close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2026-01-27 Origin: Site

If you are developing a new countertop water dispenser, a smart coffee machine, or a portable camping filter, you are likely looking at a 12V mini diaphragm water pump. It’s the perfect size, quiet, and runs efficiently on battery or wall power.

But here is the most important question you need to ask: "Is the mini water pump I’m looking at actually safe for drinking water?"

The short answer is: Not all of them. Using the wrong pump can lead to chemical leaching, bad tastes, or even health risks. Here is what you need to know to make sure your product is 100% safe for your customers.

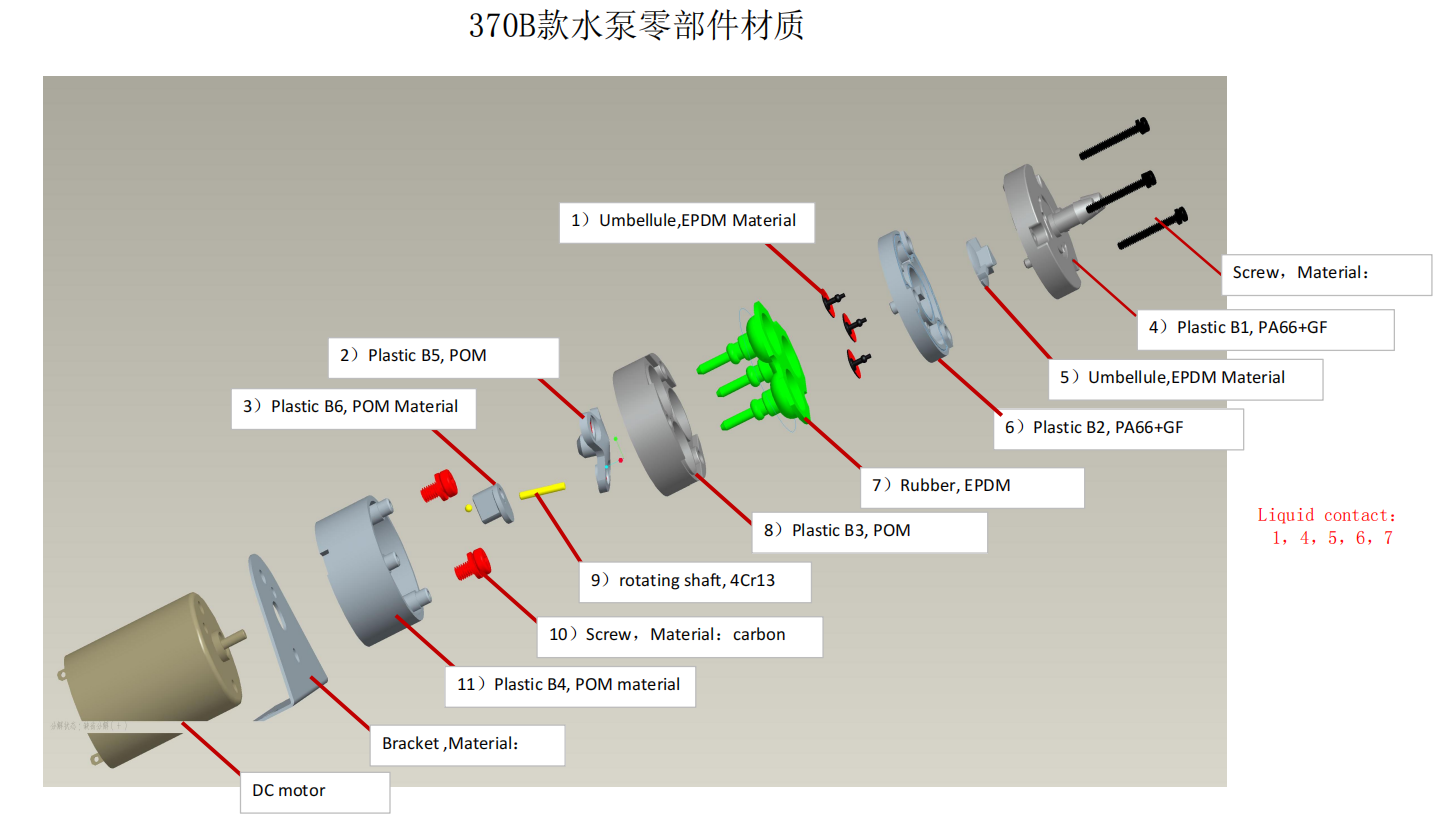

In a wholesale diaphragm pump, the liquid only touches a few parts: the pump head (housing), the diaphragm, and the valves. If these parts are made from industrial-grade plastics or recycled rubbers, they can release harmful chemicals into the water.

To ensure safety, you must look for these specific materials:

The Housing: Look for Food-Grade PP (Polypropylene) or ABS. These plastics do not contain BPA and are stable when in contact with water.

The Diaphragm & Valves: This is where most mistakes happen. Standard pumps use NBR (Nitrile). For drinking water, you must use Food-Grade Silicone or Certified EPDM. These materials are odorless, non-toxic, and resistant to bacterial growth.

Have you ever taken a sip of water from a new machine and noticed a strong, chemical, or "rubbery" taste? That is a red flag.

This usually happens when a manufacturer uses low-quality industrial rubber to save costs. Not only is this unpleasant for the user, but it also means the rubber is breaking down into the water. At Pincheng Motor, we use high-purity elastomers that have been tested to ensure they leave zero taste or odor in the water, even after the 6V food grade mini water pump has been sitting idle.

Some types of pumps require internal lubrication (oil) to keep the motor or gears running. If a seal fails, that oil can leak into the drinking water.

Diaphragm pumps are naturally "Oil-Free." Because the diaphragm creates a total physical barrier between the motor and the water chamber, there is zero risk of mechanical lubricants contaminating the drink. This is why diaphragm technology is the #1 choice for the food and beverage industry.

When you are sourcing a 12V pump for coffee machine , don’t just take the supplier’s word for it. Look for compliance with international safety standards:

RoHS & REACH: Ensures the pump contains no heavy metals or hazardous chemicals.

FDA Grade Materials: Confirms that the parts touching the water meet U.S. Food and Drug Administration standards.

CE Certification: Ensures the electrical components are safe and won't overheat.

Choosing a cheap, industrial-grade pump for a drinking water application is a shortcut that can lead to product recalls and unhappy customers.

At Shenzhen Pincheng Motor, we take food safety seriously. We offer a specialized line of 3.7V Mini Diaphragm Water Pumps designed specifically for the beverage industry. Our pumps feature:

100% Food-Grade Silicone diaphragms.

BPA-Free pump housings.

Brushless DC (BLDC) options for a cleaner, longer-lasting machine.

Ready to build a safer product?Our team can provide you with material safety data sheets (MSDS) and help you select the right food-safe pump for your specific project.